Guide to Conducting Gas Equipment Maintenance Safety Checks, Including Leak Detection and Knowing When to Call a Professional

Gas equipment is an integral part of many households and businesses, providing heat, cooking, and other essential functions. However, it is crucial to ensure the safe operation of gas equipment to prevent accidents and potential hazards. Regular maintenance and safety checks are necessary to keep your gas equipment in good working condition, detect any leaks, and address potential issues before they become major problems.

One of the most critical aspects of gas equipment maintenance is leak detection. Gas leaks can be extremely dangerous, as they can lead to fires, explosions, and serious health risks. It is essential to regularly inspect your gas equipment for any signs of leaks, such as a distinctive smell, hissing sounds, or unusually high gas bills. If you suspect a gas leak, it is crucial to take immediate action and call a professional for assistance.

While some gas equipment maintenance tasks can be performed by homeowners or business owners, certain situations require the expertise of a professional. For example, if you notice any significant issues with your gas equipment, such as a malfunctioning pilot light, inconsistent heating or cooking performance, or unusual noises, it is best to call a licensed and experienced technician to diagnose and address the problem. Attempting to fix complex gas equipment issues without proper training can be dangerous and may cause further damage.

In conclusion, maintaining the safety and proper functioning of your gas equipment is essential for the well-being of your household or business. Regular maintenance checks, including leak detection, are crucial for preventing accidents and potential hazards. If you notice any signs of gas leaks or significant issues with your gas equipment, it is recommended to call a professional technician for assistance. By prioritizing gas equipment maintenance and safety, you can ensure the efficient and safe operation of your gas appliances for years to come.

What is a gas service?

A gas service refers to the regular maintenance and inspection of gas equipment in order to ensure its safe operation. It involves a series of safety checks and leak detection procedures to identify any potential issues or hazards. Gas services are typically performed by trained professionals who are licensed to handle gas equipment.

During a gas service, the technician will inspect the gas equipment, including gas pipes, valves, and appliances, to make sure they are in proper working condition. They will also check for any signs of leaks, such as a gas odor or hissing sound. If a leak is detected, the technician will take immediate action to fix the issue and ensure the safety of the premises.

Gas services are important for several reasons. Firstly, they help to prevent accidents and potential gas leaks, which can lead to fires, explosions, or carbon monoxide poisoning. Regular maintenance also helps to prolong the lifespan of gas equipment and ensure its efficient operation. Additionally, gas services are often required by law in many jurisdictions to ensure the safety of occupants and comply with regulations.

It is recommended to have a gas service performed at least once a year, although the frequency may vary depending on the type of gas equipment and its usage. It is important to hire a qualified and licensed professional to perform the gas service to ensure that all safety checks and maintenance procedures are carried out correctly.

In conclusion, a gas service is an essential maintenance procedure for gas equipment to ensure its safe operation and prevent potential hazards. Regular gas services help to detect and fix any issues or leaks, prolong the lifespan of the equipment, and ensure compliance with safety regulations.

What’s included in gas service

Gas service typically includes a range of maintenance tasks to ensure the safe and efficient operation of gas equipment. These tasks may vary depending on the specific equipment being serviced, but generally include:

| Inspection | A thorough inspection of the gas equipment to check for any signs of damage or wear. This may involve visually inspecting components, such as pipes and valves, and checking for any leaks. |

| Cleaning | Removing any dirt, debris, or rust that may have accumulated on or around the gas equipment. This can help prevent clogs or blockages that could affect the equipment’s performance. |

| Testing | Conducting various tests to ensure the gas equipment is functioning properly. This may include checking gas pressure, testing ignition systems, and verifying that safety features are working correctly. |

| Adjustment | Making any necessary adjustments to the gas equipment to optimize its performance. This may involve calibrating controls, adjusting fuel-to-air ratios, or fine-tuning other settings. |

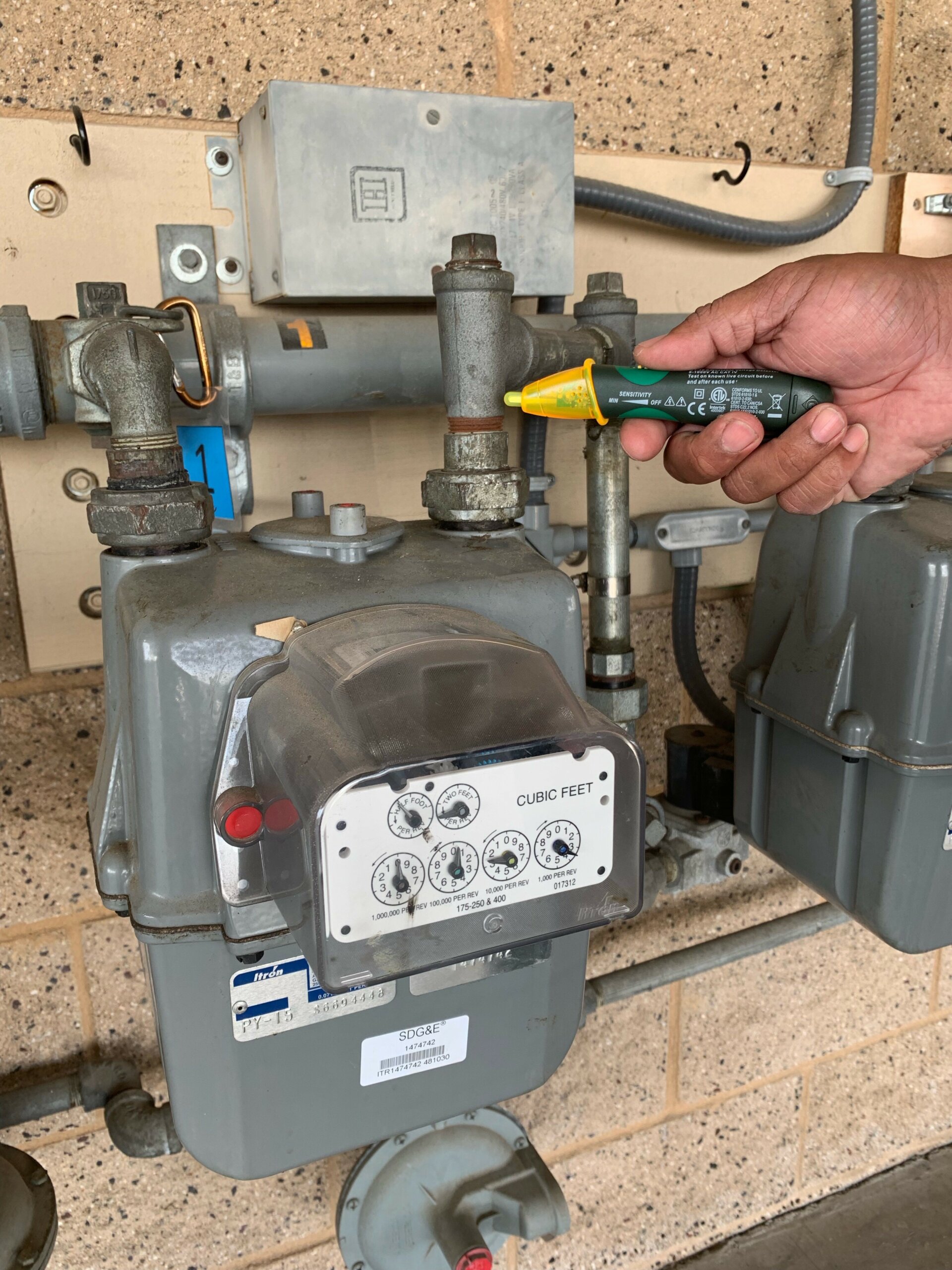

| Leak detection | Using specialized tools and techniques to detect any gas leaks. This is a critical task as gas leaks can be extremely dangerous and need to be addressed immediately. |

| Documentation | Providing detailed documentation of the gas service, including any repairs or maintenance performed, as well as any recommendations for future maintenance or upgrades. |

It’s important to have gas service performed regularly and by a qualified professional to ensure the safety and efficiency of your gas equipment. Regular maintenance can help prevent costly repairs and extend the lifespan of your equipment.

Who can perform gas service

When it comes to gas service, it is important to hire qualified professionals to ensure your safety and the proper functioning of your gas equipment. Only individuals who have the necessary training and certification should be trusted to perform gas service tasks.

Qualified professionals who can perform gas service include:

- Gas service technicians: These professionals are trained to install, repair, and maintain gas equipment. They have the knowledge and skills to handle gas-related tasks safely and efficiently.

- Gas engineers: Gas engineers specialize in designing and installing gas systems. They have a deep understanding of gas regulations and can ensure that gas installations meet safety standards.

- Gas safety inspectors: These professionals carry out inspections to ensure that gas systems and equipment comply with safety regulations. They can identify potential hazards and recommend necessary repairs or improvements.

It is important to check the qualifications and certifications of any professional you hire for gas service. Make sure they are properly licensed and have a good reputation in the industry. Hiring an unqualified individual can put your safety at risk and may result in costly repairs or accidents.

Remember, gas service should never be attempted by untrained individuals. Gas leaks and faulty equipment can pose serious risks, including fire, explosions, and carbon monoxide poisoning. If you suspect a gas leak or encounter any issues with your gas equipment, it is crucial to call a professional immediately.

By hiring qualified professionals for gas service, you can ensure the safety and efficiency of your gas equipment and minimize the risk of accidents or hazards.

Service frequency

Regular maintenance of gas equipment is essential to ensure its safe and efficient operation. The frequency of service depends on the type of equipment and its usage. Here are some general guidelines for service frequency:

| Type of Equipment | Recommended Service Frequency |

|---|---|

| Gas boilers | Annually |

| Gas furnaces | Annually |

| Gas water heaters | Every 2-3 years |

| Gas stoves and ovens | Every 2-3 years |

| Gas dryers | Every 2-3 years |

| Gas fireplaces | Every 2-3 years |

| Gas grills | Every 2-3 years |

It’s important to note that these are general recommendations and the service frequency may vary depending on the manufacturer’s instructions and the specific conditions of use. Additionally, if you notice any signs of malfunction or gas leaks, you should immediately contact a professional for inspection and repair.

Can I service my own boiler?

Servicing your own boiler can be a tempting option, especially if you are someone who enjoys DIY projects. However, it is important to consider the risks and potential dangers involved before attempting to service your own boiler.

Boiler servicing requires specialized knowledge and expertise to ensure that the system is properly maintained and operating safely. It involves tasks such as inspecting and cleaning the burners, checking for gas leaks, and testing the boiler’s safety controls.

Attempting to service your own boiler without the necessary skills and knowledge can result in serious accidents, such as gas leaks or carbon monoxide poisoning. These risks can have severe consequences for you and your household.

Additionally, DIY boiler servicing may void your warranty or insurance coverage. Most manufacturers and insurance policies require that a qualified professional service the boiler to maintain coverage. If you attempt to service the boiler yourself and something goes wrong, you may be left responsible for any damages or repairs.

For these reasons, it is strongly recommended to hire a professional to service your boiler. A qualified technician will have the necessary training and experience to ensure that your boiler is serviced safely and effectively. They can identify any potential issues and address them before they become major problems.

Regular boiler servicing is essential for maintaining the efficiency and safety of your heating system. By scheduling professional maintenance on a regular basis, you can ensure that your boiler operates at peak performance, minimizes energy consumption, and maximizes its lifespan.

In conclusion, while it may be tempting to service your own boiler, it is best to leave this task to the professionals. Hiring a qualified technician will help ensure that your boiler is serviced safely and effectively, reducing the risk of accidents and maintaining the efficiency of your heating system.

Precautions for DIY servicing

While it is possible to perform some maintenance tasks on gas equipment yourself, it is important to take certain precautions to ensure your safety and the effectiveness of the maintenance. Here are some precautions to keep in mind:

| Precaution | Description |

|---|---|

| Turn off the gas supply | Before starting any maintenance work, make sure to turn off the gas supply to the equipment. This will prevent any accidental gas leaks or potential hazards. |

| Use proper tools and equipment | Make sure to use the correct tools and equipment for the maintenance tasks. Using improper tools can lead to damage or accidents. |

| Follow manufacturer’s instructions | Always refer to the manufacturer’s instructions for any maintenance procedures. This will ensure that you are following the correct steps and using the appropriate methods. |

| Wear protective gear | When working with gas equipment, it is important to wear the necessary protective gear, such as gloves and safety glasses. This will protect you from any potential harm or accidents. |

| Check for leaks | After performing any maintenance tasks, thoroughly check for gas leaks. Use a gas leak detector or soapy water to identify any leaks. If you detect a leak, turn off the gas supply and contact a professional immediately. |

| Keep a fire extinguisher nearby | As a precautionary measure, always have a fire extinguisher nearby when performing any maintenance on gas equipment. This will ensure that you are prepared to handle any fire emergencies that may arise. |

While DIY servicing can be a cost-effective option, it is important to remember that some tasks should only be performed by a qualified professional. If you are unsure about any aspect of the maintenance or if you encounter any issues, it is always best to call a professional for assistance.

Expert recommendations

When it comes to gas equipment maintenance and safety checks, it is always recommended to hire a professional. They have the knowledge and experience to properly inspect and maintain your gas equipment, ensuring it is in good working condition and safe to use.

Leak detection is a crucial aspect of gas equipment maintenance. If you suspect a gas leak, it is important to take immediate action. Open windows and doors to ventilate the area, avoid using any electrical devices or open flames, and evacuate the premises. Call a professional gas technician to locate and repair the leak.

It is important to know when to call a professional. If you notice any of the following signs, it is time to seek expert help:

- Unusual smells: If you detect a strange odor, like rotten eggs, it could be a sign of a gas leak.

- Unexplained increase in gas bills: If your gas bills have been steadily increasing without any apparent reason, it could indicate a gas leak or inefficient gas equipment.

- Strange noises: If you hear hissing or whistling sounds near your gas equipment, it could be a sign of a leak or malfunction.

- Yellow or flickering pilot light: A pilot light that is not blue and steady could indicate a problem with your gas appliance.

- Difficulty starting or operating equipment: If you are having trouble starting or operating your gas equipment, it is best to have a professional inspect it.

Remember, gas equipment can be dangerous if not properly maintained and checked for leaks. It is always wise to rely on the expertise of a professional to ensure the safety and efficiency of your gas appliances.

Alternatives

If you are concerned about the safety of using gas equipment or if you are unable to perform the maintenance checks and leak detection yourself, there are alternatives available. One option is to hire a professional gas technician to regularly inspect and maintain your gas equipment. These professionals have the knowledge and expertise to ensure that your equipment is functioning properly and safely.

Another alternative is to switch to electric equipment. Electric appliances do not require gas and therefore eliminate the need for maintenance checks and leak detection. Electric equipment is also considered safer as there is no risk of gas leaks or explosions. However, it is important to note that electric equipment may have its own maintenance requirements and should be used and maintained according to the manufacturer’s instructions.

Ultimately, the decision to use gas or electric equipment depends on your specific needs and preferences. If you choose to use gas equipment, it is crucial to prioritize safety by regularly performing maintenance checks and leak detection or by hiring a professional to do so. If you prefer the peace of mind that comes with not having to worry about gas leaks, electric equipment may be the better option for you.

Regardless of the alternative you choose, it is important to stay informed about gas equipment safety and to know when to call a professional for help. Gas leaks can be dangerous and should be taken seriously. If you smell gas or suspect a leak, evacuate the area immediately and call a professional gas technician or emergency services.

How often should a gas pipe be tested?

Regular testing of gas pipes is essential to ensure the safety of your gas equipment and to prevent any potential leaks or hazards. The frequency of testing depends on various factors, including the type of gas being used, the age of the gas pipes, and the regulations and guidelines set by local authorities.

As a general guideline, it is recommended to have a professional conduct a gas pipe test at least once every two years. This will help identify any potential issues or leaks before they become major problems. However, if you notice any signs of a gas leak, such as a strange odor, hissing sounds, or a sudden increase in your gas bill, it is important to have the gas pipes tested immediately, regardless of the last testing date.

In addition to regular testing, it is important to visually inspect your gas pipes on a regular basis. Look for any signs of corrosion, damage, or loose fittings. If you notice any issues, it is important to have them addressed by a professional as soon as possible.

It is also important to note that certain situations may require more frequent testing. For example, if you have recently installed new gas pipes or if you have made any modifications to your gas system, it is recommended to have a professional test the pipes before using them.

Overall, the frequency of gas pipe testing depends on several factors, including the type of gas being used and the regulations in your area. It is always best to consult with a professional to determine the appropriate testing schedule for your specific situation.

| Signs of a gas leak | Actions to take |

|---|---|

| Strange odor | Immediately turn off the gas supply, open windows and doors to ventilate the area, and contact a professional. |

| Hissing sounds | Evacuate the area immediately and contact emergency services. |

| Sudden increase in gas bill | Contact a professional to inspect the gas pipes and identify any potential leaks. |

Recommended frequency

Regular maintenance and safety checks for gas equipment are crucial for ensuring its proper functioning and preventing leaks. The frequency of these checks will depend on several factors, including the type of equipment, its age, and usage. However, it is generally recommended to have gas equipment inspected and serviced at least once a year by a qualified professional.

For residential gas appliances, such as water heaters, boilers, and stoves, an annual maintenance check is usually sufficient. This check should include a thorough inspection of the equipment, cleaning of components, testing for leaks, and ensuring proper ventilation. Additionally, it is important to perform regular visual checks for any signs of damage or wear and tear.

In commercial settings, where gas equipment is often used more frequently and subjected to heavier loads, more frequent maintenance checks may be necessary. Depending on the specific equipment and its usage, quarterly or biannual inspections might be recommended.

It’s important to note that certain gas appliances, such as gas detectors and carbon monoxide alarms, may have their own recommended maintenance schedules. It is essential to follow the manufacturer’s guidelines for these devices to ensure their accuracy and reliability.

While regular maintenance and safety checks can help prevent potential issues, it is also important to be vigilant for any signs of gas leaks or malfunctioning equipment. If you notice any unusual smells, hissing sounds, or other signs of a gas leak, it is vital to take immediate action. In such cases, you should evacuate the premises, avoid using any electrical appliances or switches, and contact a professional gas engineer or your local gas provider.

Remember, gas equipment maintenance and safety checks should always be performed by qualified professionals who are trained in gas safety. They have the knowledge and expertise to identify potential issues and ensure the safe operation of your gas equipment.

Who should perform the check

Performing gas equipment maintenance safety checks and leak detection requires specialized knowledge and expertise. It is crucial to ensure that the person conducting the check is qualified and trained in gas safety procedures. Therefore, it is recommended to hire a professional gas technician or a licensed plumber to perform these checks.

Professional gas technicians have the necessary skills and experience to identify and fix any potential issues with gas equipment. They are trained in leak detection methods and can accurately assess the condition of the system. Hiring a professional ensures that the check is performed correctly and reduces the risk of accidents or further damage.

Attempting to perform the check without proper knowledge and training can be extremely dangerous. Gas leaks can lead to explosions, fires, and health hazards. It is always best to leave gas equipment maintenance and leak detection to the professionals who have the expertise to handle these tasks safely and effectively.

In addition to hiring a professional, it is important to schedule regular check-ups and maintenance for gas equipment. This will help ensure that any potential issues are addressed promptly, preventing major problems in the future.

Overall, when it comes to gas equipment maintenance safety checks and leak detection, it is best to rely on professionals who have the necessary qualifications and experience. Their expertise will ensure that the check is performed accurately and safely, minimizing the risk of accidents and ensuring the efficient operation of gas equipment.

What’s checked during testing

During gas equipment maintenance safety checks, several important components and systems are inspected to ensure their proper functioning and to detect any potential leaks. Here are some of the main aspects that are typically checked:

- Gas connections: The connections between gas pipes, appliances, and fittings are thoroughly examined for any signs of damage, corrosion, or loose connections. Any issues found are addressed and repaired to prevent leaks.

- Gas valves: All gas valves, including shut-off valves and control valves, are inspected to ensure they are working correctly and are not leaking. If any valves are found to be faulty, they are repaired or replaced.

- Pilot lights: For appliances with pilot lights, such as gas stoves or water heaters, the pilot lights are checked to ensure they are lit and burning properly. If the pilot light is not functioning correctly, it may indicate a problem with the gas supply or the appliance itself.

- Gas pressure: The gas pressure is checked to ensure it is within the safe and recommended range. If the pressure is too high or too low, it can affect the performance and safety of the equipment. Adjustments are made if necessary.

- Ventilation: Proper ventilation is crucial for gas appliances to ensure the safe removal of combustion byproducts. The ventilation system is inspected to ensure it is clear of obstructions and functioning properly.

- Gas detectors: Gas detectors are used to check for the presence of gas leaks. These detectors are highly sensitive and can quickly identify even small amounts of gas in the air. They are tested to ensure they are working properly and calibrated correctly.

It’s important to note that gas equipment maintenance safety checks should be performed by qualified professionals who have the necessary knowledge and experience. They can identify any potential issues and take the appropriate actions to ensure the safety and proper functioning of the gas equipment.

What safety checks are required for gas appliances?

Regular safety checks for gas appliances are essential to ensure the proper functioning and safety of your gas equipment. Here are some important safety checks that should be performed:

- Inspect for signs of damage or wear on the gas pipes, connections, and hoses. Any cracks, leaks, or corrosion should be immediately addressed by a qualified professional.

- Check for proper ventilation and ensure that the flue and air vents are clear from obstructions. Blocked vents can lead to a buildup of carbon monoxide, which is extremely hazardous.

- Verify that the burner flames are blue and stable. Yellow or flickering flames could indicate a problem with the combustion process and should be investigated further.

- Test the gas pressure to ensure it is within the recommended range. Low or high gas pressure can affect the efficiency and safety of the appliance.

- Inspect the pilot light, if applicable, and ensure it is lit and functioning correctly. A pilot light that frequently goes out or produces a weak flame may indicate a problem.

- Check the operation of safety features such as flame failure devices and carbon monoxide detectors. These are important safeguards that should be regularly tested to ensure they are working properly.

- Inspect the appliance’s controls and valves. Ensure they are functioning correctly and not damaged or stuck.

It is important to note that gas appliance safety checks should only be performed by qualified professionals who have the necessary training and expertise. If you have any concerns about the safety of your gas appliances or suspect a gas leak, it is essential to call a professional immediately. Gas leaks can be extremely dangerous and should never be ignored.

Leak check

Regular leak checks are an essential part of gas equipment maintenance. Gas leaks can be extremely dangerous, as they can lead to fires, explosions, and serious health hazards. It is important to conduct leak checks on a regular basis to ensure the safety of your gas equipment and the people around it.

There are several ways to perform a leak check. One common method is using soapy water. Mix a small amount of dish soap with water and apply it to the gas equipment connections, valves, and fittings. If there is a leak, bubbles will form, indicating the presence of a gas leak. Another method is using a gas leak detector, which can detect even the smallest leaks by sensing the gas in the air.

When performing a leak check, pay close attention to the following areas:

- Gas equipment connections

- Valves

- Fittings

- Pipes

If you detect a gas leak during the check, it is important to take immediate action. Here’s what you should do:

- Turn off the gas supply.

- Open windows and doors to ventilate the area.

- Do not use any electrical devices or open flames.

- Evacuate the area and call a professional gas technician.

It is crucial to never attempt to fix a gas leak yourself, as this can be dangerous and should only be done by a qualified professional. They have the necessary training and equipment to safely repair gas leaks and ensure the continued safety of your gas equipment.

Ventilation check

Proper ventilation is essential for the safe operation of gas equipment. A ventilation check should be performed regularly to ensure that the area where the gas equipment is located has adequate airflow. This is especially important for enclosed spaces such as basements, utility rooms, or garages where gas appliances are commonly installed.

During a ventilation check, the following steps should be taken:

| Step | Procedure |

|---|---|

| 1 | Inspect the ventilation openings for any blockages or obstructions. Make sure that the vents are not covered by furniture, curtains, or other objects. |

| 2 | Check the condition of the vents. Make sure that they are not damaged or corroded. If any vent is damaged, it should be repaired or replaced as soon as possible. |

| 3 | Measure the airflow. Use a smoke pencil or a similar device to check if air is flowing in the correct direction. The smoke should be drawn into the ventilation openings and not blown out. |

| 4 | Check for any unusual smells. If there is a strong odor of gas or any other unusual smell, it may indicate a ventilation problem or a gas leak. In such cases, immediately turn off the gas equipment and contact a professional. |

If any issues are found during the ventilation check or if there are any concerns about the ventilation in the area, it is important to call a professional for further evaluation. They will be able to identify any potential problems and recommend the necessary actions to ensure proper ventilation and safety.

Safety valve check

Regularly checking the safety valve on your gas equipment is essential for maintaining a safe working environment. The safety valve is designed to release pressure if it exceeds a certain level, preventing potential accidents or damage to the equipment.

Here are the steps to perform a safety valve check:

- Start by turning off the gas supply to the equipment and allowing it to cool down.

- Inspect the safety valve for any signs of damage, such as cracks or leaks. If you notice any issues, it is important to replace the valve immediately.

- Carefully open the valve and check for any obstructions or blockages that may prevent it from functioning properly.

- Ensure that the valve is properly sealed and not loose. If it is loose, tighten it securely, but be careful not to overtighten.

- Turn on the gas supply and check if the safety valve is releasing pressure as it should. A hissing sound or the release of gas indicates that the valve is functioning correctly.

If you encounter any problems during the safety valve check or are unsure about how to perform it, it is best to call a professional gas equipment maintenance technician. They have the expertise and knowledge to address any issues and ensure the safety of your equipment.

How do I know if I have a gas leak?

If you suspect you have a gas leak in your home or workplace, it is crucial to take immediate action to ensure your safety. Gas leaks can be extremely dangerous and potentially fatal, so it’s important to know the signs of a gas leak and what steps to take if you suspect one.

1. Smell: One of the most common signs of a gas leak is the distinct odor of natural gas. Natural gas is odorless, but a chemical called mercaptan is added to give it a rotten egg or sulfur-like smell. If you notice this odor, it is a clear indication of a gas leak.

2. Hissing or Whistling Sounds: If you hear hissing or whistling sounds near a gas appliance or pipeline, it could be a sign of a gas leak. This could indicate a damaged or faulty gas line, and immediate action should be taken.

3. Dead or Discolored Plants: If you have plants or vegetation near a gas line, a gas leak can cause them to become discolored or die. Gas leaking into the soil can prevent the plants’ roots from getting oxygen, leading to their deterioration.

4. Bubbles: If you notice bubbles in standing water around your property, it could be a sign of a gas leak. Gas escaping from a pipeline can cause water to bubble or appear disturbed.

5. Physical Symptoms: Another indication of a gas leak is experiencing physical symptoms. These symptoms may include headaches, dizziness, nausea, fatigue, or difficulty breathing. If you or anyone in your vicinity experiences these symptoms, leave the area immediately and seek fresh air.

If you suspect a gas leak, it is crucial to act quickly and follow these steps:

- Do not use any electrical devices: This includes lights, switches, phones, or appliances. Sparks from electrical devices can ignite the gas and cause an explosion.

- Extinguish any open flames: This includes candles, matches, lighters, or gas stoves. Open flames can also ignite the gas and cause a fire or explosion.

- Open windows and doors: This will help ventilate the area and allow any gas to dissipate.

- Evacuate the premises: If the gas smell is strong or if you are experiencing any physical symptoms, evacuate the building immediately. Call emergency services and alert them to the potential gas leak.

- Do not return to the building: Wait for emergency services to arrive and give them any relevant information about the suspected gas leak.

Remember, gas leaks can be extremely dangerous, and it is always better to be safe than sorry. If you suspect a gas leak, do not attempt to fix it yourself. Call a professional gas technician who can locate and repair the leak safely.

Signs of a gas leak

Gas leaks can be dangerous and should be addressed immediately. It is important to know the signs of a gas leak so that you can take the necessary steps to ensure your safety and the safety of others in your home or workplace.

Here are some common signs that may indicate the presence of a gas leak:

1. Smell of gas: Natural gas is odorless, but gas companies add a distinctive smell, often compared to rotten eggs, to help people detect leaks. If you notice a strong, unpleasant odor, it could be a sign of a gas leak.

2. Hissing or whistling sounds: If you hear an unusual hissing or whistling sound near a gas appliance or pipeline, it could be a sign of a gas leak. Do not ignore this sound and take immediate action.

3. Dead or dying vegetation: Gas leaks can affect plants and vegetation in the surrounding area. If you notice dead or dying plants, especially in an otherwise healthy garden or lawn, it could be a sign of a gas leak underground.

4. Bubbles in water: If you see bubbles or a milky appearance in standing water near a gas line, it could indicate a gas leak. Gas escaping from an underground pipe can cause water to bubble or appear discolored.

5. Physical symptoms: Exposure to natural gas can cause physical symptoms such as headaches, dizziness, nausea, and difficulty breathing. If you or others in your home or workplace experience these symptoms and suspect a gas leak, evacuate the area immediately and seek medical attention.

If you notice any of these signs of a gas leak, it is important to take action quickly. Follow proper safety procedures, such as turning off the gas supply if possible, opening windows for ventilation, and leaving the area until professionals can assess and repair the leak.

Remember, gas leaks can be extremely dangerous. Always prioritize the safety of yourself and others by promptly addressing any signs of a gas leak and seeking professional assistance when needed.

Using a gas detector

Gas detectors are essential tools for ensuring the safety of gas equipment and detecting potential leaks. When using a gas detector, it is important to follow these steps:

- Read the manual: Before using a gas detector, always read the manufacturer’s instructions and familiarize yourself with the device’s features and functions.

- Turn on the detector: Ensure that the gas detector is turned on and properly calibrated according to the manufacturer’s guidelines.

- Check the sensor: Inspect the sensor for any damage or debris that may affect its accuracy. Clean the sensor if necessary.

- Approach the area: Slowly approach the area where you suspect a gas leak, keeping the detector in front of you at all times.

- Monitor the readings: Pay close attention to the gas detector’s readings. If the detector detects a high level of gas concentration, it will typically emit an audible alarm or flash a warning light.

- Take action: If the gas detector indicates a gas leak, immediately leave the area and call a professional for assistance. Do not attempt to fix the leak yourself.

Remember, gas detectors should be regularly tested and maintained to ensure their accuracy and reliability. If you are unsure about how to use a gas detector or suspect a gas leak, always contact a professional for help.

What to do if a leak is detected

If you detect a gas leak in your gas equipment, it is important to take immediate action to ensure your safety. Follow these steps to effectively handle the situation:

| Step 1: | Evacuate the area. If you smell gas or suspect a leak, evacuate the premises immediately. Gas leaks can be highly dangerous and can lead to explosions or fires. |

| Step 2: | Do not use any electrical switches or devices. Avoid using any electrical switches, including lights, appliances, or even your cell phone, as they can create sparks that may ignite the gas. |

| Step 3: | Open windows and doors. If it is safe to do so, open windows and doors to ventilate the area and allow any gas to dissipate. This can help reduce the risk of explosion. |

| Step 4: | Turn off the gas supply. If you know how to safely do so, turn off the gas supply at the main valve. This will help stop the flow of gas and minimize the risk of further leaks. |

| Step 5: | Call a professional. Contact a licensed gas technician or emergency services to report the leak and seek professional assistance. They will have the expertise and equipment to safely locate and repair the leak. |

Remember, gas leaks are serious and should not be taken lightly. Always prioritize your safety and follow the proper procedures when dealing with a gas leak.

When should a gas engineer be called?

If you notice any signs of a gas leak or suspect a problem with your gas equipment, it is important to call a qualified gas engineer immediately. Gas leaks can be extremely dangerous and should never be ignored.

Some signs that may indicate a gas leak include a strong smell of gas, hissing or whistling sounds near gas appliances, or dead plants or vegetation near a gas line. If you experience any of these signs, it is crucial to take immediate action.

A gas engineer should also be called if your gas equipment is not functioning properly. This could include issues such as low gas pressure, a pilot light that keeps going out, or strange noises coming from your gas appliances. Ignoring these problems can lead to further damage or even a potential safety hazard.

It is important to remember that working with gas can be dangerous and should only be handled by trained professionals. Gas engineers are highly skilled and have the knowledge and experience to safely repair and maintain gas equipment. They are also equipped with the necessary tools and equipment to accurately detect and fix gas leaks.

Attempting to fix gas equipment yourself or hiring an unqualified individual can put you and your household at risk. It is always best to call a professional gas engineer to ensure the safety of your home and loved ones.

Regular maintenance and safety checks are also important to prevent gas leaks and ensure the proper functioning of your gas equipment. A gas engineer can perform these checks and identify any potential issues before they become major problems.

In conclusion, a gas engineer should be called when there is a suspected gas leak, problems with gas equipment, or for regular maintenance and safety checks. It is always better to be safe than sorry when dealing with gas, so do not hesitate to call a professional if you are unsure or concerned about any gas-related issues.

Signs of gas equipment malfunction

If you suspect that your gas equipment is malfunctioning, it is important to address the issue immediately to prevent any potential hazards. Here are some signs that may indicate a problem with your gas equipment:

- Unusual or strong odors: If you smell a strong odor of gas, it may indicate a gas leak. Gas leaks can be dangerous and should be addressed immediately.

- Yellow or flickering flames: Gas appliances should have a steady blue flame. If you notice a yellow flame or flickering flames, it may indicate a problem with the burner or gas supply.

- Soot or black marks: Soot or black marks around your gas equipment may indicate incomplete combustion. This can be a sign of a blocked or dirty burner, which can affect the efficiency and safety of the equipment.

- Carbon monoxide detector alarm: If your carbon monoxide detector goes off, it could indicate a problem with your gas equipment. Carbon monoxide is a colorless and odorless gas that can be produced by faulty gas appliances.

- Unexplained increase in gas bills: If you notice a sudden and unexplained increase in your gas bills, it may indicate that your gas equipment is not functioning properly and is using more gas than necessary.

- Difficulty starting or operating equipment: If you are experiencing difficulty starting or operating your gas equipment, it may indicate a problem with the ignition system, gas valve, or other components.

If you notice any of these signs, it is important to take immediate action. Contact a professional gas technician to inspect and repair your gas equipment. Do not attempt to fix the problem yourself, as it can be dangerous and may void any warranties or insurance coverage.

In case of gas supply shutdown

If you experience a gas supply shutdown, it is important to take the following steps to ensure your safety and the safety of those around you:

1. Do not attempt to relight any gas appliances. When the gas supply is shut off, it is important not to try to relight any gas appliances. This includes stoves, ovens, water heaters, and furnaces. Attempting to relight these appliances without proper training and knowledge can be dangerous and lead to gas leaks or explosions.

2. Open windows and doors to ventilate the area. If you smell gas or suspect a leak, open windows and doors to allow fresh air to circulate and help remove any potentially harmful gas fumes from the area. This can help reduce the risk of gas buildup and potential explosions.

3. Leave the premises immediately. If you suspect a gas leak or experience a gas supply shutdown, it is important to leave the premises immediately. Do not stay in the building or attempt to fix the issue yourself. Call a professional gas technician or the gas company’s emergency hotline to report the issue and seek assistance.

4. Avoid using any electrical devices. When there is a gas supply shutdown or a suspected gas leak, it is important to avoid using any electrical devices, including light switches, appliances, or electronic devices. These can create sparks and potentially ignite any gas that may be present in the area.

5. Do not smoke or use open flames. Smoking or using open flames, such as matches or lighters, can ignite any gas that may be present in the area. It is important to refrain from smoking or using open flames until the gas supply is restored and the area is deemed safe by a professional.

Remember, in case of a gas supply shutdown or suspected gas leak, it is always best to err on the side of caution and seek professional help. Gas leaks can be extremely dangerous and should be addressed by trained professionals.

For routine maintenance

Regular maintenance of gas equipment is essential to ensure its safe and efficient operation. Here are some important steps to follow for routine maintenance:

- Inspect the equipment: Regularly check the gas equipment for any signs of damage, such as cracks or leaks. Pay close attention to the hoses, connections, and valves.

- Clean the equipment: Keep the gas equipment clean from dust, dirt, and debris. Use a soft cloth or brush to remove any build-up that may obstruct the proper functioning of the equipment.

- Check for leaks: Perform leak detection tests on a regular basis. Use a gas leak detector or soapy water solution to check for any gas leaks. If you detect a leak, take immediate action to address the issue.

- Test safety features: Test the safety features of the equipment, such as emergency shut-off valves and pressure relief valves, to ensure they are functioning correctly.

- Review manufacturer’s instructions: Refer to the manufacturer’s instructions for specific maintenance requirements and recommended intervals for routine maintenance.

It is important to remember that routine maintenance should be carried out by trained professionals who have the necessary knowledge and expertise. They can identify potential issues and address them before they become more serious problems.

By performing routine maintenance on your gas equipment, you can ensure its longevity, efficiency, and most importantly, the safety of yourself and others.

Q&A:

What are some common gas equipment maintenance safety checks?

Some common gas equipment maintenance safety checks include checking for any signs of damage or wear, ensuring proper ventilation, inspecting gas connections for leaks, and making sure all safety devices are working correctly.

How can I detect a gas leak in my home?

You can detect a gas leak in your home by using your senses. Look for any visible signs of a gas leak, such as a discolored or dying vegetation near gas lines. Listen for any hissing sounds. Smell for the distinct odor of natural gas, which is similar to rotten eggs. If you suspect a gas leak, it’s important to evacuate the area immediately and call a professional.

What should I do if I detect a gas leak?

If you detect a gas leak, you should immediately evacuate the area and call a professional. Do not use any electrical devices, open flames, or create any sparks that could ignite the gas. It’s important to inform others in the vicinity about the gas leak and ensure that everyone is safely out of harm’s way.

When should I call a professional for gas equipment maintenance?

You should call a professional for gas equipment maintenance if you notice any unusual smells, sounds, or signs of a gas leak. It’s also recommended to have a professional inspect your gas equipment on a regular basis to ensure it is in proper working condition and to prevent any potential safety hazards.

What are the consequences of not properly maintaining gas equipment?

The consequences of not properly maintaining gas equipment can be serious. It can lead to gas leaks, which can result in fires, explosions, or carbon monoxide poisoning. Neglecting gas equipment maintenance can also decrease the efficiency and lifespan of the equipment, leading to higher energy costs and the need for expensive repairs or replacements.

What are some safety checks that should be performed during gas equipment maintenance?

During gas equipment maintenance, it is important to perform safety checks such as inspecting gas lines for leaks, checking for proper ventilation, ensuring proper gas pressure, and inspecting and testing safety devices.